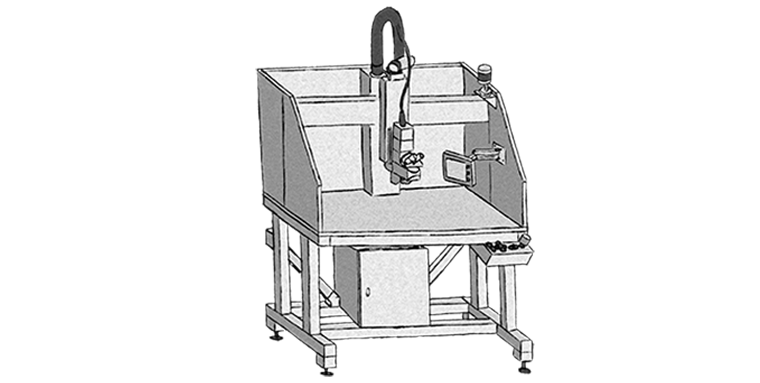

Manual laser welding machine – Basic

Entry into hand-guided, manual welding

Greatest possible freedom with a small footprint

High resolution stereo microscope with crosshairs

Description

As a basic model, the HLA-B offers the entry into hand-guided, manual welding. Different welds can be easily realized by working freely, directly on the component. Due to its open design, the HLA offers the greatest possible degree of freedom with a small footprint. The high-resolution stereo microscope offers the machine operator a direct, absolutely precise view of the work area. In combination with the enormous depth of focus, welding results of the highest quality can be achieved on the HLA-B.

Handling

The HLA-B is parameterized by means of the operating panel of the selected laser source. The laser beam and the protective gas supply can be controlled via a 2-step foot switch. The amount of shielding gas can be adjusted directly on the stereomicroscope via a control valve. The motorized Z-axis allows easy focus height adjustment.

Technical data

HLA-B

Footprint

Approx. 1200x900x2700 mm (W/D/H)

Weight

Approx. 300 kg

Connection data

230V / 2A

Working space

Approx. 1100x760x300 mm (W/D/H)

Workpiece weight

Max. 50 kg

Z-axis travel

300 mm unregulated

Basic configuration

HLA-B

Machine control

None

Handling

Machine: 2-way pushbutton for Z-axis

NC drives

DC drive

Safety functions

Laser safety circuit

Safety sensors

Working area monitoring in laser safety circuit

Machine frame

Aluminum system profile

Machine enclosure

Sheet steel, color RAL 7016 (others upon request)

Laser source & welding optics

Customer & application specific

Extraction system

Customer & application specific

Machine equipment

Not configurable

Anfrage / Request

Ich interessiere mich für eine Fertiglösung von WEISSER / I am interested in a ready-to-use solution from WEISSER